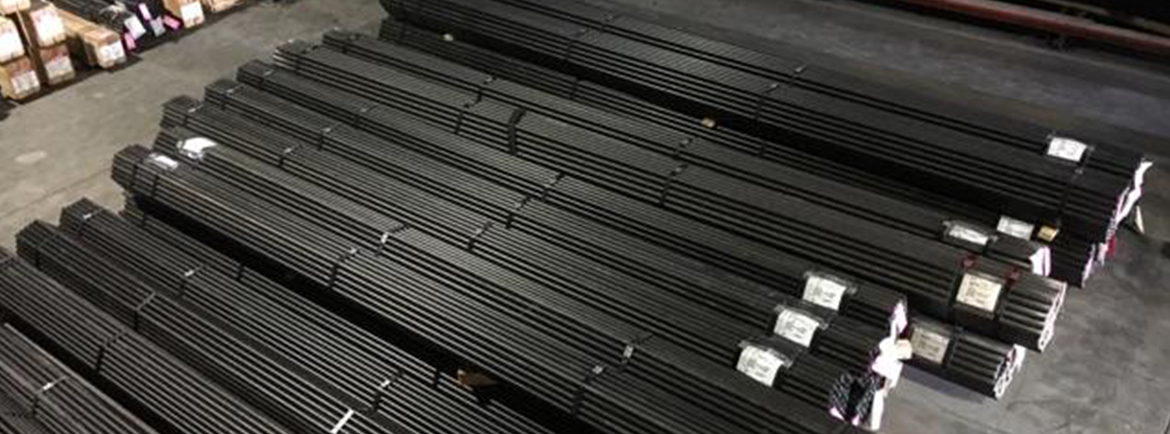

Drawn Over Mandrel (DOM) Carbon Steel Tubing

OD & ID, OD & Wall, ID & Wall, ASTM A-513 Type 5 C1026, C1020 Grades

Features:

- An excellent general purpose tubing selection.

- Greater wall uniformity due to method of manufacture. (Controlled strip, rolled & welded then drawn over a mandrel through a die)

- Greater concentricity than seamless tubing.

- Good physical characteristics. DOM possesses a high strength to weight ratio.

- Size range is limited only by the ability to weld strip to produce hollows to be drawn.

- Chemistries limited only by ability to weld strip for hollows.

- All DOM tubing is eddy current tested.

- DOM tubing possesses a superior ID and OD surface finish compared to other types of tubing

- Because of method of manufacture –controlled strip, slit, rolled, welded, and drawn over a mandrel through a die, DOM tubing possesses an excellent microstructure enhanced through the cold working and forming.

Benefits:

- DOM tubing because of tight tolerance production and uniformity of wall as well as microstructure makes a good or preferred choice for cylinders, sleeves, bushings, axles, and shafting

- Customers can save on machining costs due to the ability to order and receive material which is closer to their actual finished size requirements

- Tighter tolerances allow customers to save on scrap loss, machining costs and freight costs

- Customers can save on machining time, machine tool costs and in some cases eliminate machining all together

- Available in 1/8” OD to 15” OD by .020” to .625” wall thicknesses

- Typically available from the mill as C1020 for .134 wall and under and C1026 for heavier wall thicknesses. DOM is also available in C10 –10, 20, 35, 40, ST52 and in many 4130 sizes

- Because of controlled strip and cold rolling and drawing DOM tubing typically possesses 70,000 –85,000 tensile and a 60,000 –75,000 yield, an elongation of 8 –10%

- Guaranteed weld integrity of welded hollows. Customers can request hydrostatic testing at an additional charge

- Due to controlled strip, and cold forming, the surface finish of DOM is often found to be suitable to end use in an as is condition

- To many customers, DOM tubing machines better than HFSM or CDSM this is probably a result of less machining time but the impression is one that can be exploited

Note 1: DOM tubing is produced with a 7 foot spread, typically 17ft to 24ft random lengths. Cut to length or dead lengths are produced at normally a 5% premium. Customers may place orders with mills for a minimum of 5000’/#’s of an item. Traditionally, producer price breaks occur at 10,000’/#’s, 20,000’/#’s, 40,000’/#’s and 100,000’/#’s. Some Group 1 mill producers will accept orders for 2500’/#’s but usually at a pricing premium.

Size Range Available: 1/8” OD –15” OD by .020” -.625” walls

Chemistries Available: C1020 in .134” walls or lighter, C1026 in .134” walls and heavier

Also available in C10-10,30,35,40 ST52 Grade and in some 4130 sizes. Most service centers /distributors order and stock DOM in a stress relieved condition, often as stress relieved annealed

OD Finish Available: CQ -Commercial Quality, Pickled & Oiled, brite-annealed

Note 2: DOM is a globally produced commodity. Globally the following criteria is used to determine product grouping: Group 1

Outside Diameter 4.000” OD (or smaller) x .134” wall or lighter.

Group 2

Outside Diameter under 4.000” OD x .135” wall up to and including .375” wall.

Any size 4.000” OD through 7.000” OD x .134” wall up to .320” wall.

Group 3

Outside Diameter 2.000” OD x .376” wall and heavier, 4.000” OD or larger size with any wall thickness heavier than .320” wall and any wall thickness of any size over 7.000” OD.